Paletizing

Palletiser M4000S

The M4000S palletiser is a high production machine for use with the most demanding applications in terms of performance and quality of pallet presentation.

It can palletise 25, 30, 35, 40 and 50 kg bags or others depending on the specific requirements of each application.

Its special design represents an innovation in the field of bag palletising. The incorporated distribution system enables high performance operation at low linear speeds, preventing the deforming of bags.

The machine’s design concept, as with all of Metral’s products, is characterised by great robustness and simplicity.

Format changes are quick and simple. The machine can be fitted with an automatic regulation system that enables all of its elements to be positioned by simply selecting the necessary program from the operating terminal.

Palletiser M2400S

The M2400S palletiser is a standard machine suitable for multiple applications, producing between 1.500 to 3.000 bags/hour, depending on pallet format and bag characteristics.

Its modular design provides numerous combinations to adapt to the production needs and available space of each application.

A personalised study in collaboration with the client is the usual way of obtaining the best possible technical solution.

Palletiser MP1200S

The MP1200S palletiser has been specially designed for plastic bags or materials that are difficult to handle.

The difference with respect to other models is that the process is carried out using a single sluice.

All of our machines feature a layer pressing system with a pressure limiting device. This system ensures a perfect finish in terms of appearance and stability.

Our product portfolio also includes different types of auxiliary equipment for bag preparation, marking, gluing and layer to layer pressing, etc, in addition to other peripheral equipment, such as the hydraulic pallet press and machines for wrapping, shrink wrapping, stretch hooding, stretch wrapping and complete lines for creating shrink wrapped loads without wooden pallets (pallet-less).

Robot

More than 30 years of experience in the palletising field and the use of new technology enables us to provide a comprehensive and efficient solution to the process of palletising boxes, bags, tins, boards, bottles, etc.

Robot palletising cells are ideal for use in small spaces and provide a degree of automation to suit the client’s needs.

The flexibility of this type of machine means that it can operate with several formats and palletising stations simultaneously (up to 6 pallets simultaneously). Changes in format and layout settings can be carried out quickly and easily from the operating terminal.

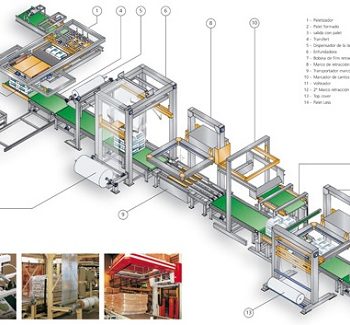

Palet-less

The pallet-less range produces shrink wrapped loads with the bags at the bottom arranged in such a way as to enable the forks of the forklift to be inserted and the load transported just like a normal pallet.

As pallets are not necessary, the logistical issues associated with wooden pallets are avoided. In addition, shrink wrapping in plastic provides a much higher degree of protection. This allows the pallets to be stored in the open air and product preservation is improved.

In the case of cement, ageing is delayed for at least two months compared to other palletising methods.

The total cost of the plastic and energy used in the shrink wrapping process is less than half the cost of wooden pallets.